Calenders

Hot calenders

The Sicam hot calendar can be supplied with two or three rolls, driven dried by a cardanic shaft system and independent motors and can be heated by:

– direct electric heating

– diathermic oil heated by electric resistance or gas boiler

In the calenders with oil heating system, Sicam uses high flow pumps which allow to keep at low level the temperature delta between the entrance and the exit of the oil from the rolls, to obtain a perfect temperature uniformity on the surface of the roll to obtain a top of quality nonvowen.

This temperature uniformity is obtained also thanking to the high speed oil circulation inside the roll in proper channels.

According to the company philosophy, Sicam carefully chooses the materials and the thermic treatment of the rolls of the machine according to the request of the technological process.

The rolls are built in a special steel which then after thermical treatment reach a very high hardness not only on the surface , but also in the deep thickness .

The shaft of the rolls are obtained from forged pieces , in order to keep the structural continuity of the steel and to reach a high toughness.

Calenders for lines for the production of needle punched felts (Geotestile) working with 8000mm , rolls diameter 830mm.

In order to obtain the thickness uniformity of the nonwoven Sicam has studied solution according to the experience and the innovation.

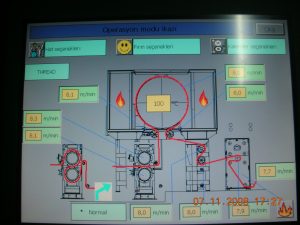

From the operator panel is possible to control the distance between the rolls, controlled by proper motorized screw jacks and by a special software which keep constant the distance of the rolls with a compensation of the diameter variation for the temperature.

The Sicam hot calenders are provided with a flexion compensation device by cross axis or using special rolls with fixed or variable bombage.

The Sicam hot calenders, thanked to particular hardness of the rolls can solve the problems of the production lines in order to ensure the production continuity and to minimize the maintenance time.

Their application is in fact particularly suitable, for example, in the lines for the production of Geotestile, where the rolls hardness is very important to solve the problem of any broken needles in the nonwoven.

In fact these needles don’t cause any interruption to the production because they don’t do any damage to the Sicam calendar. The surface of the roll remains flat also after many years of production avoiding in this way high maintenance costs of the changing of the rolls. This result is due to the special care that Sicam has for the quality of its production which makes real benefit for the customer.

– special calendars placed after thermofixing or thermobonding ovens.

– special connecting channels between oven and calenders allows that the material reaches the calenders in the best temperature condition to obtain the right final effect.

This calenders are provided with particular device for the temperature regulation which allows to heat or to cool the rolls according to the different technological requests.

Technical features

| Working with: |

1000-4500 mm |

| Production speed: |

10-500 m/min |

| Maximum working temperature: |

250 °C |

| Heating systems: |

Electrical resistance

Diathermical oil electrical heated or by gas boiler |

| Working pressure: |

10-20 kg/cm |

| Roll shape: |

cylindrical or bombage shape |

| Roll surface: |

Hardened, Teflon coated, Chromium plated |

| Rolls hardness: |

induction treatment in the thickness 62 hrc |

| Adjusting of the distance between the rolls: |

hydraulicall nitriding treatment or pneumatic |